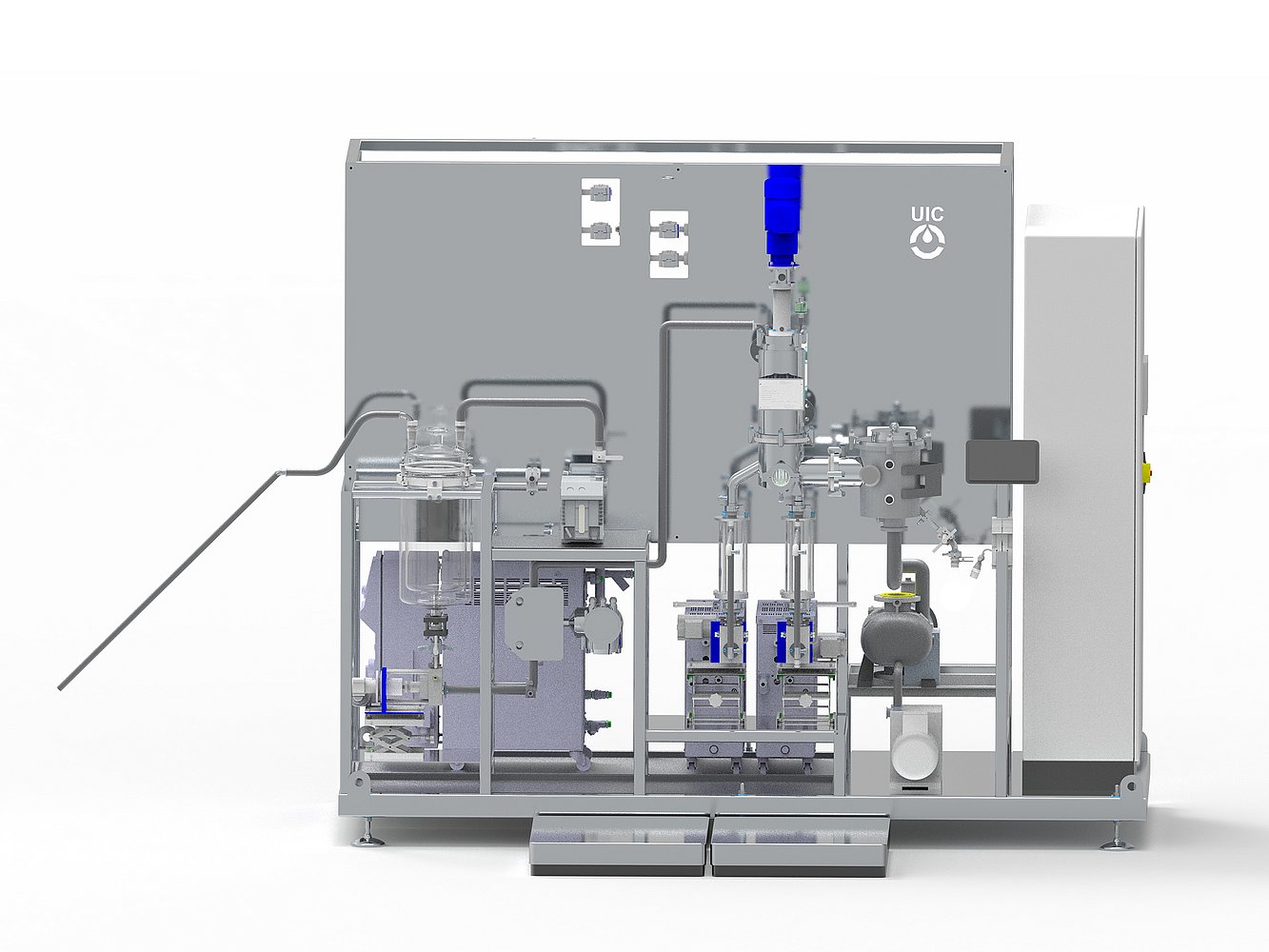

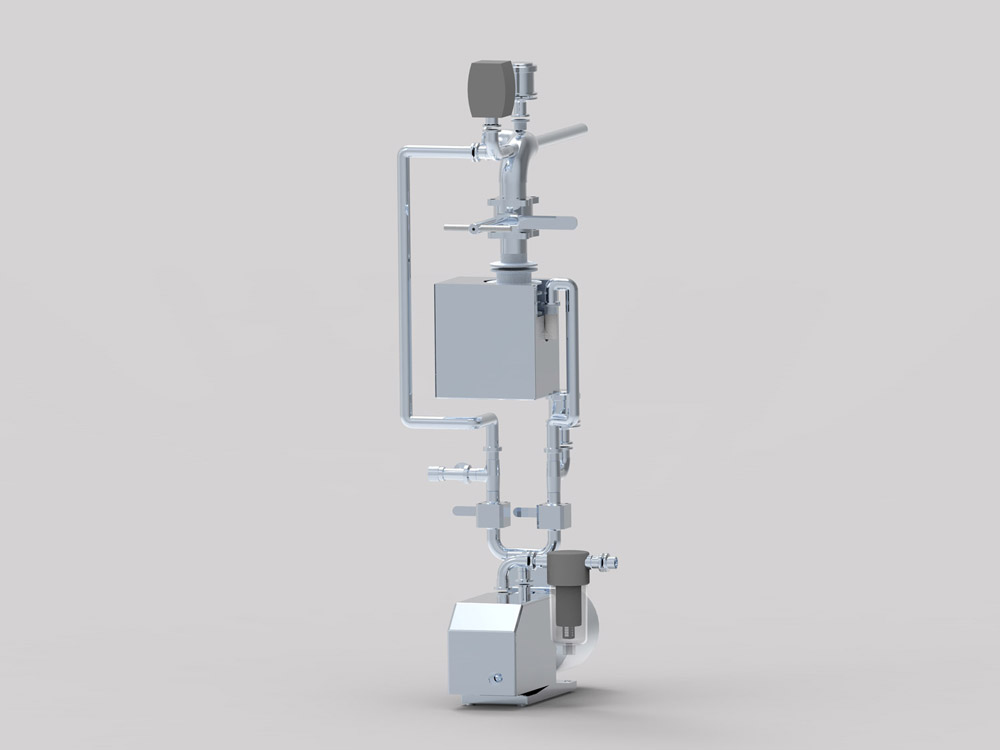

Short path distillation in a stainless steel pilot plant with 0.06 m2 wiped heating surface.

KD6 units are suitable for various throughputs at evaporator temperatures of up to 350 °C and pressures of up to 10-3 mbar.

Discover the wide range of applications for our multipurpose systems.

Our customers highly appreciate the following key benefits of our pilot plants:

The KD6 is our most compact pilot plant for short path distillation. It is ideal for process development and small-scale production on a tight budget. The fully heatable unit can be used for the continuous distillation of both high and low viscosity products. Unlike the KD10, the KD6 does not have a degassing stage. Standard configuration:

Are you interested in a specific spare part?

We will be happy to help you.

The KD6 can be equipped with the following accessories to adapt it to your distillation tasks and preferences:

The suction lance incl. a small vacuum system for the feed container enables continuous filling of the evacuated feed container directly from the vessel in which the feed material is provided (e.g. from canisters, drums or IBC containers).

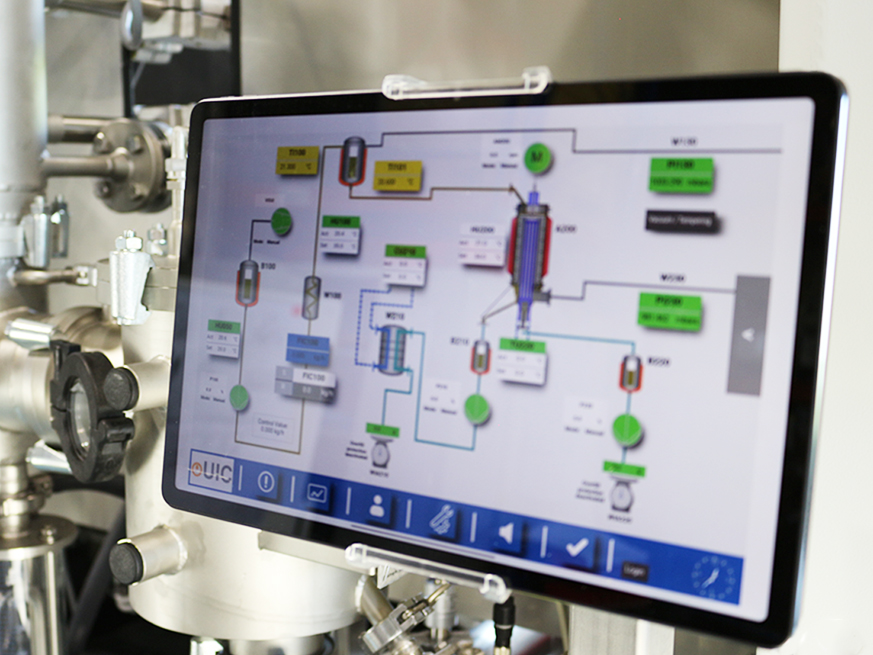

Tablet control with interface to all temperature control units, pumps, sensors and the vacuum system as well as a weighing system for distillate and concentrate.

Discover our V-Tab video right away!

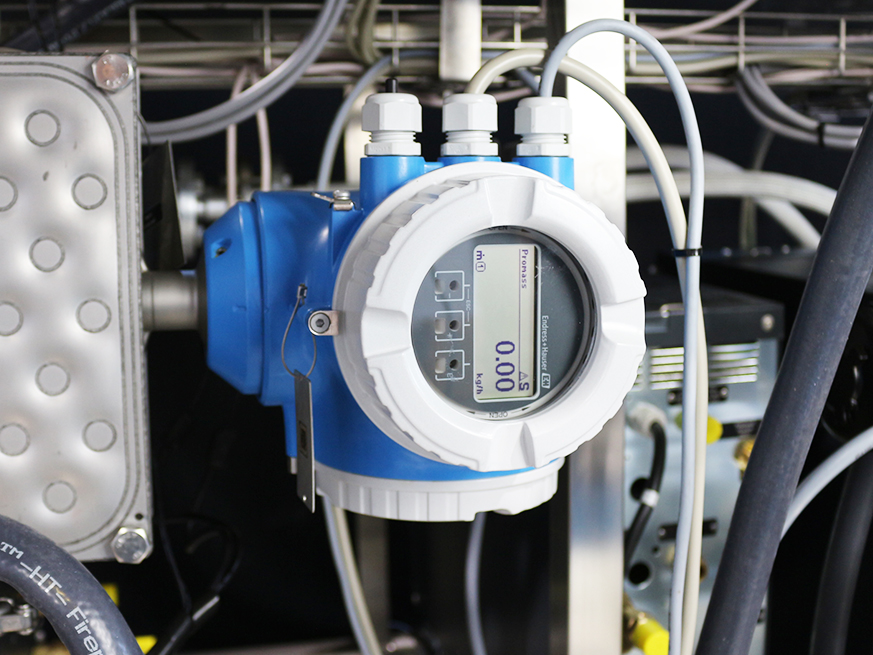

Precise and continuous feed flow measurement and control of the feed pump.

This option is only available in combination with V-Tab.

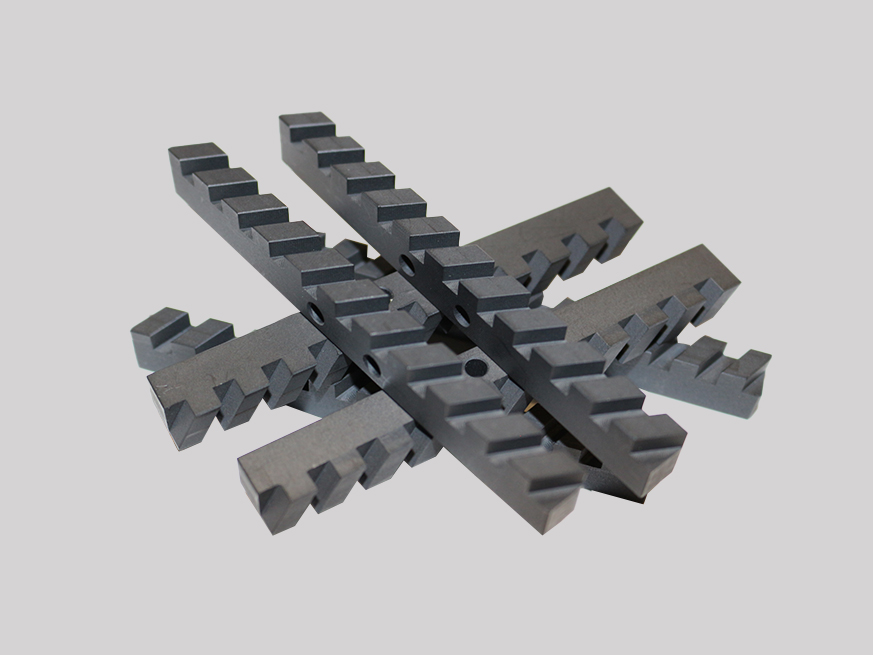

A block wiper system that comes instead of or in addition to the standard roll wiper system.

Recommended for products with viscosities above 1,000 mPas or products that tend to polymerize.

Additional tempering unit for the complete concentrate discharge line for individual temperature control. Of particular relevance e.g. in distillation processes in which the concentrate is the valuable product and reacts sensitively to prolonged exposure to heat.

Continuously cooled plug-in cooler eliminates the need for manual coolant replenishment.

Extends the vacuum system consisting of a rotary vane pump, to achieve lower working pressures of up to 10-3 mbar.