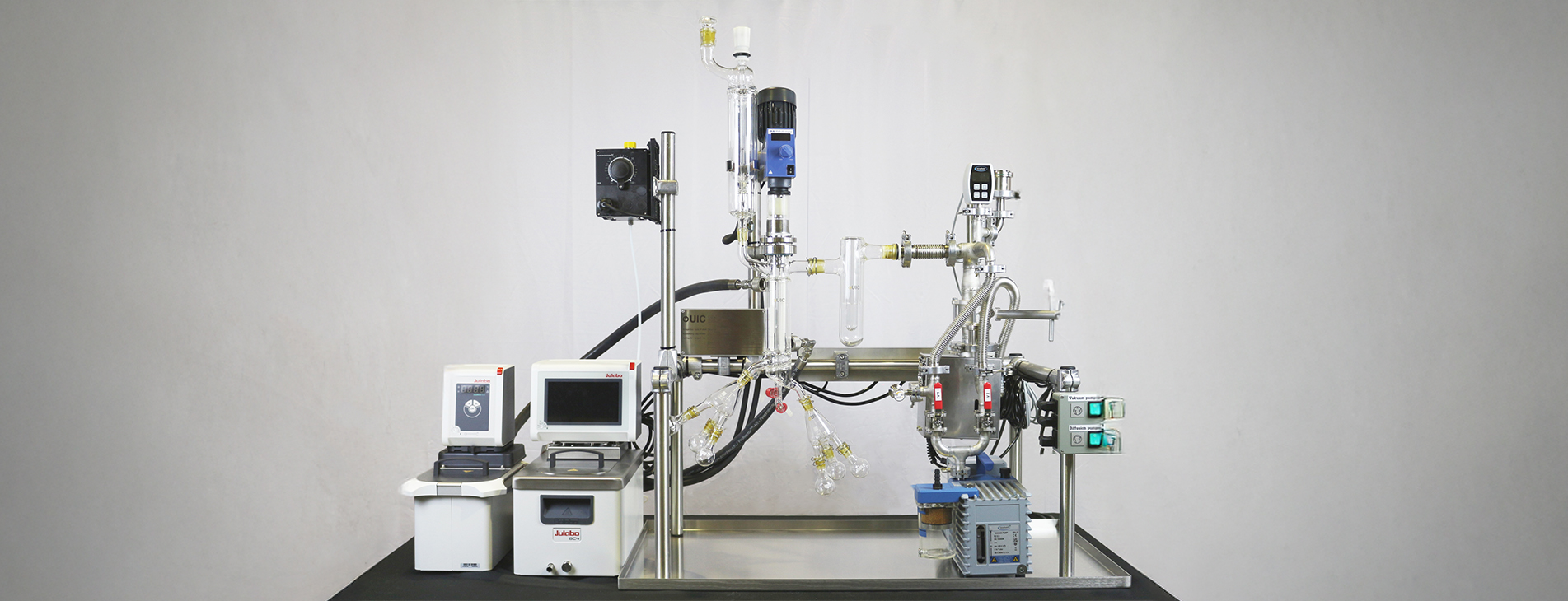

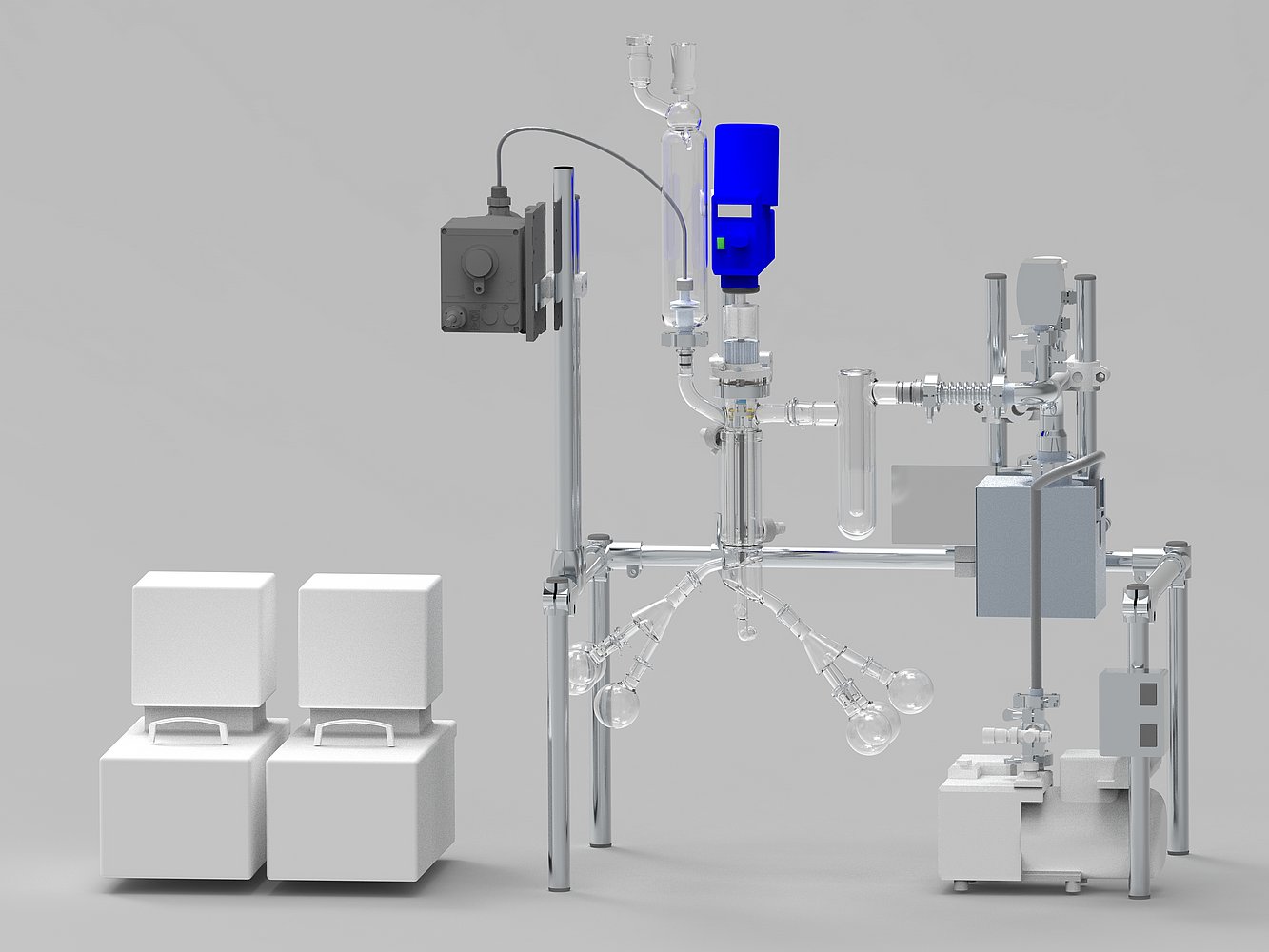

Short path distillation in a glass plant with 0.01 m2 wiped heating surface.

KDL1 units are suitable for various throughputs at evaporator temperatures of up to 250 °C and reduced pressure conditions of up to 10-3 mbar.

Discover the wide range of applications for our multipurpose systems.

The KDL1 is our smallest but still powerful glass laboratory unit for short path distillations. It is ideal for the distillation of very small quantities and for laboratory tests. It is designed for the distillation of liquid or low-viscosity products (at room temperature). The KDL1 enables semi-continuous distillation in which up to two different cuts can be taken without having to interrupt the distillation process in a vacuum. The system is operated manually.

Are you interested in a specific spare part?

We will be happy to help you.

You can equip KDL1 with accessories to adapt it to your distillation tasks and expand the performance spectrum.

With the appropriate optional accessories, you can use KDL1 even to distil products which are of high viscosity or solid at room temperature.

The following options are available to upgrade your KDL1:

A heated 250 ml dosing vessel (max. heating up to 150 °C, incl. corresponding heater) replaces the standard feed system.

Enables continuous supply of feed product. Delivered in addition to the standard feed system.

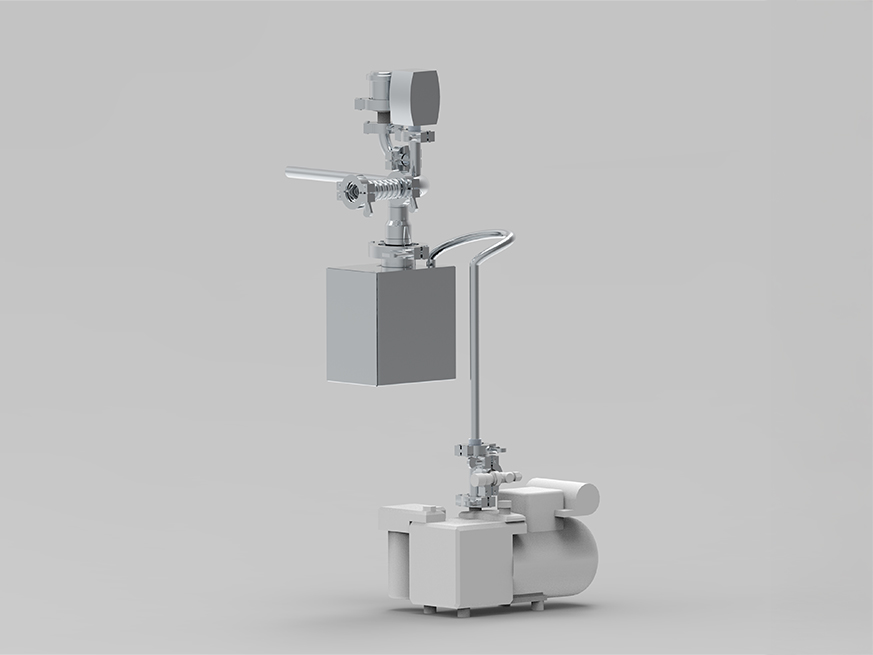

Adds an oil diffusion pump to the existing vacuum system. This allows working pressures down to 0.001 mbar.

For working temperature ranges from +20 bis +250 °C. Replaces the circulation thermostat supplied as standard (working temperature range: +20 bis +200 °C).