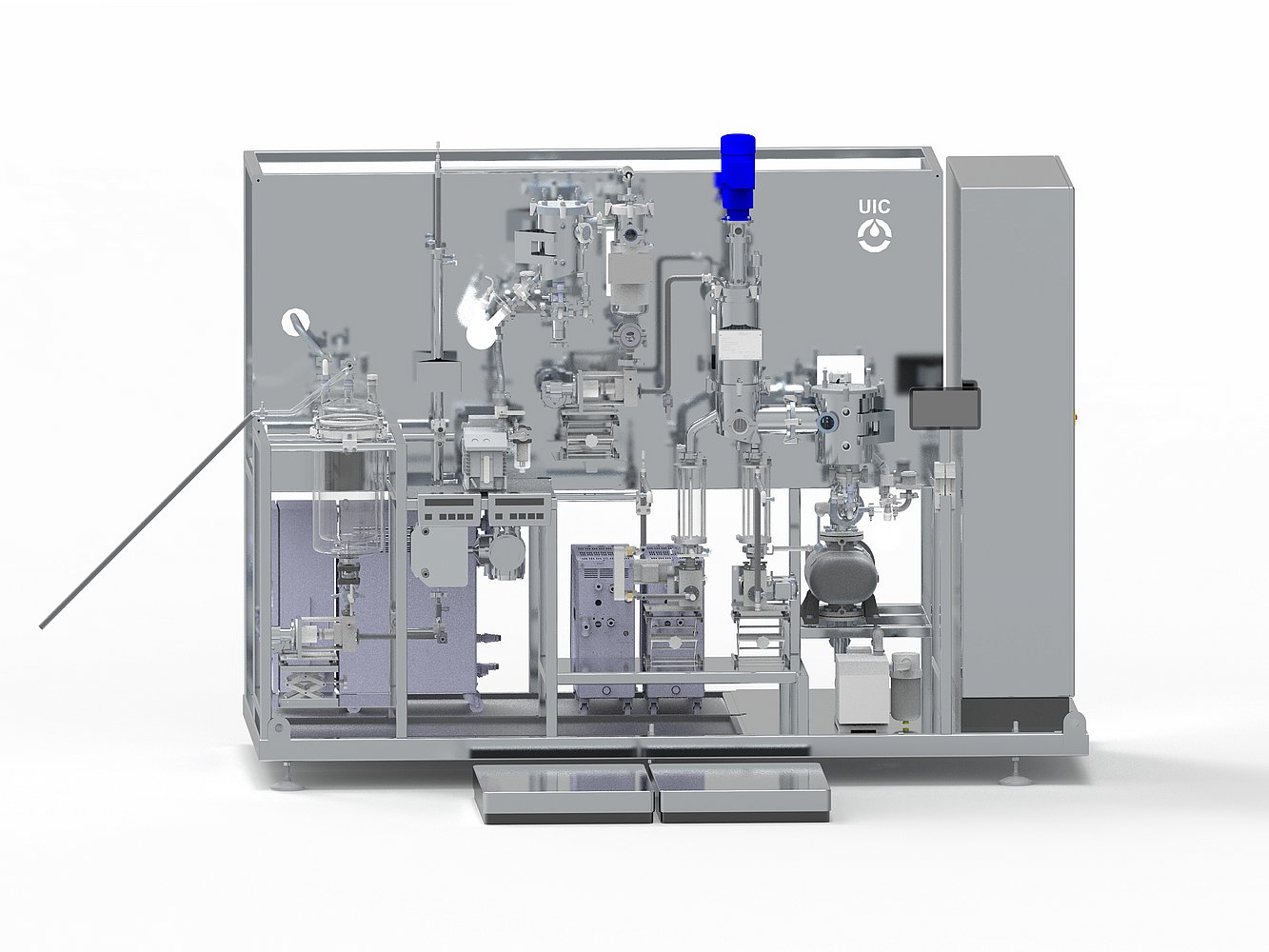

Kurzwegdestillation in einer Pilotanlage aus Edelstahl mit 0,1 m2 gewischter Beheizungsfläche.

KD10 Anlagen sind geeignet für verschiedene Durchsätze bei Verdampfertemperaturen von bis zu 350 °C und Drucken von bis zu 10-3 mbar.

Entdecken Sie hier die vielfältigen Einsatzgebiete unserer Multipurpose-Anlagen.

Unsere Kunden schätzen unsere Pilotanlagen insbesondere als …

Die KD10 ist unsere beliebteste Pilotanlage für die Kurzwegdestillation. Sie ist ideal für die Verfahrensentwicklung und Kleinmengenproduktion. Die Anlage ist hochflexibel und kann sowohl für die Destillation von hoch- als auch niedrigviskosen Produkten eingesetzt werden, da sie vollbeheizbar ist. Die KD10 destilliert kontinuierlich und verfügt über eine vorgeschaltete Entgaserstufe. Standardausstattung:

Interessieren Sie sich für ein bestimmtes Ersatzteil?

Wir helfen Ihnen gerne weiter.

Die KD10 kann, zur Anpassung an ihre Destillationsaufgaben und Präferenzen, mit folgendem Zubehör ausgestattet werden:

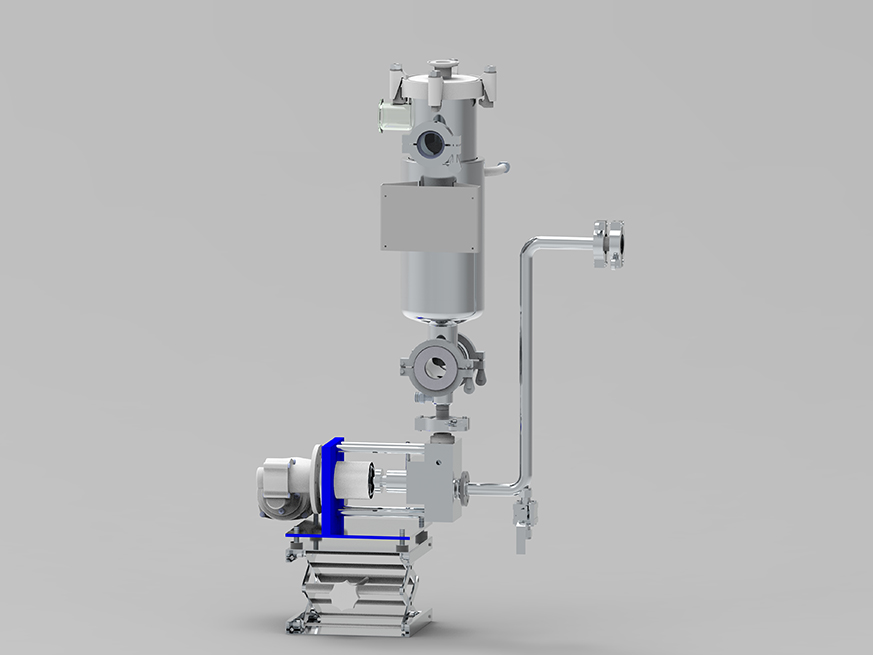

Die Ansauglanze mit kleinem Vakuumsystem für den Feed-Behälter ermöglicht die kontinuierliche Befüllung des evakuierten Feed-Behälters direkt aus den Gebinden, in denen das Feed-Material bereitgestellt wird (bspw. aus Kanistern, Fässern oder IBC Containern).

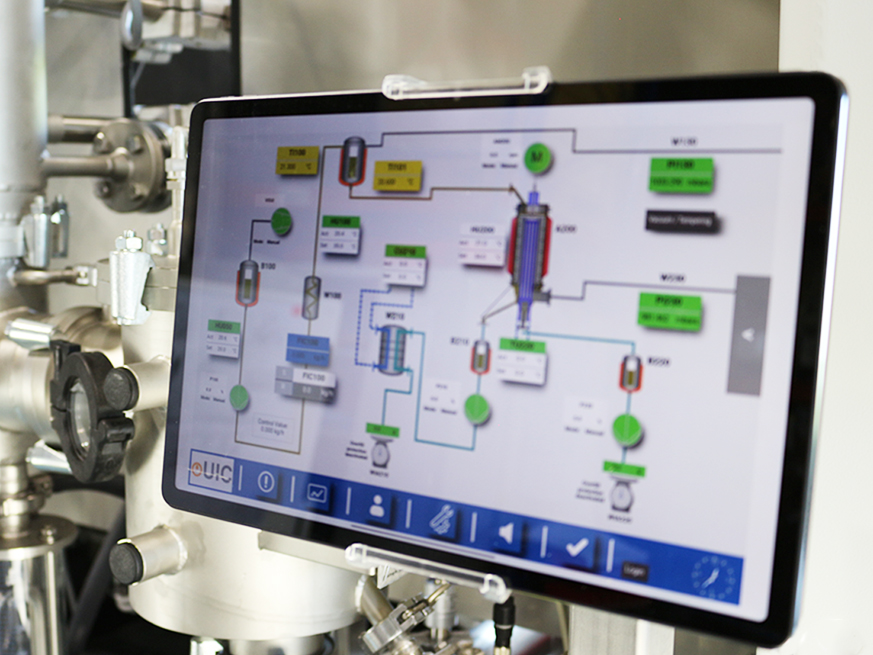

Tablet-Steuerung mit Schnittstelle zu allen Temperiergeräten, Pumpen, Sensoren und dem Vakuumsystem sowie einem Wiegesystem für Destillat und Konzentrat.

Mehr Infos im Video – jetzt ansehen!

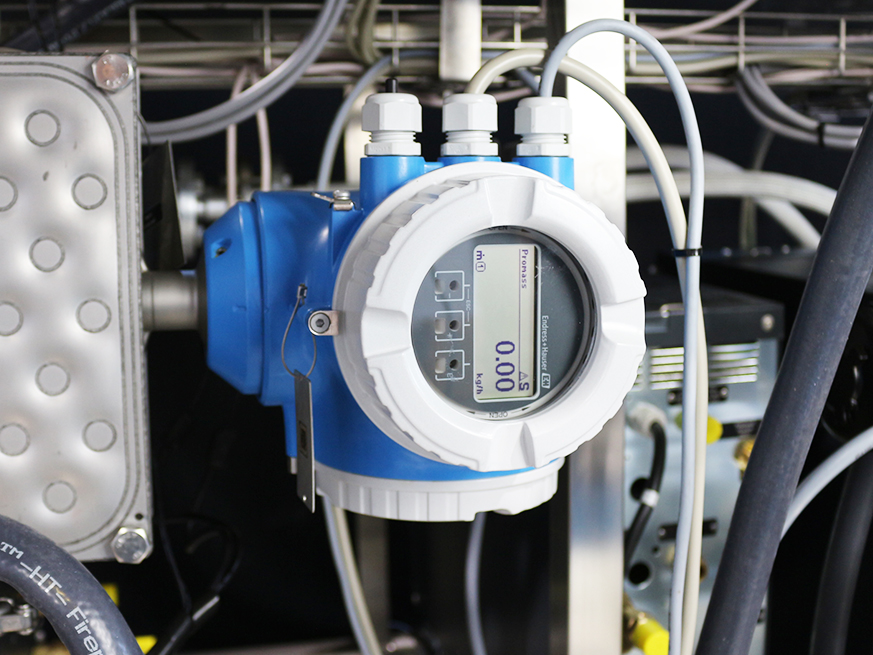

Präzise und kontinuierliche Messung des Feed-Durchflusses und Regelung der Einförderpumpe.

Diese Option ist nur in Kombination mit V-Tab verfügbar.

Eine Pumpe zwischen Entgaser und Verdampfer, die den standardmäßig an dieser Stelle verbauten Siphon ersetzt. Wird benötigt, wenn die Leichtsieder des zu destillierenden Produkts hinsichtlich ihres Siedepunkts sehr stark von der Hauptfraktion abweichen.

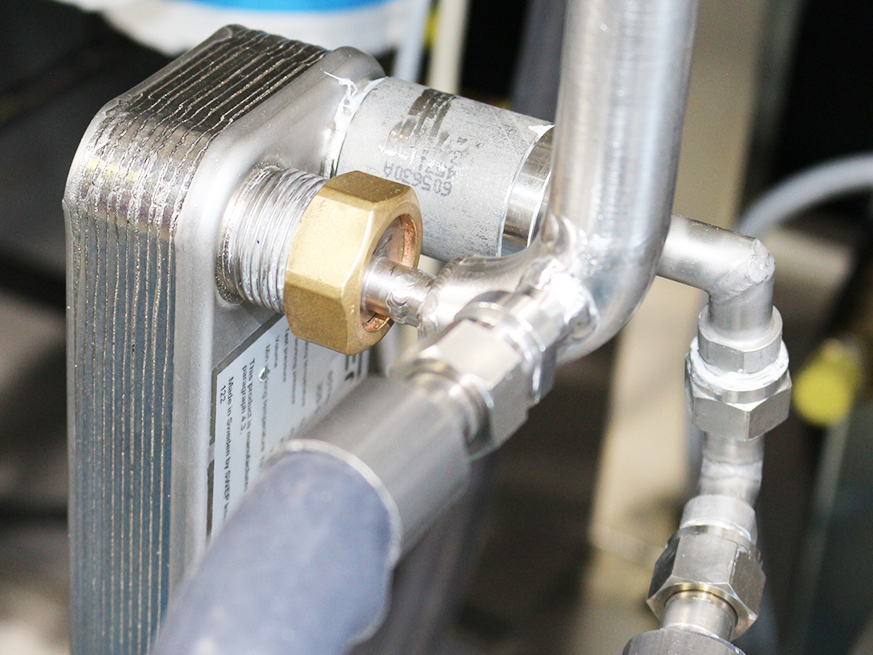

Zusätzlicher Wärmetauscher am Konzentrataustrag zur schnellen Kühlung des Konzentrats. Von besonderer Relevanz z. B. bei Destillationsprozessen, in denen das Konzentrat das Wertprodukt ist und empfindlich auf längere Hitzeexposition reagiert.

Manuelle Kühlmittelnachfüllung entfällt durch die kontinuierlich gekühlte Einsteckkühlschlange.

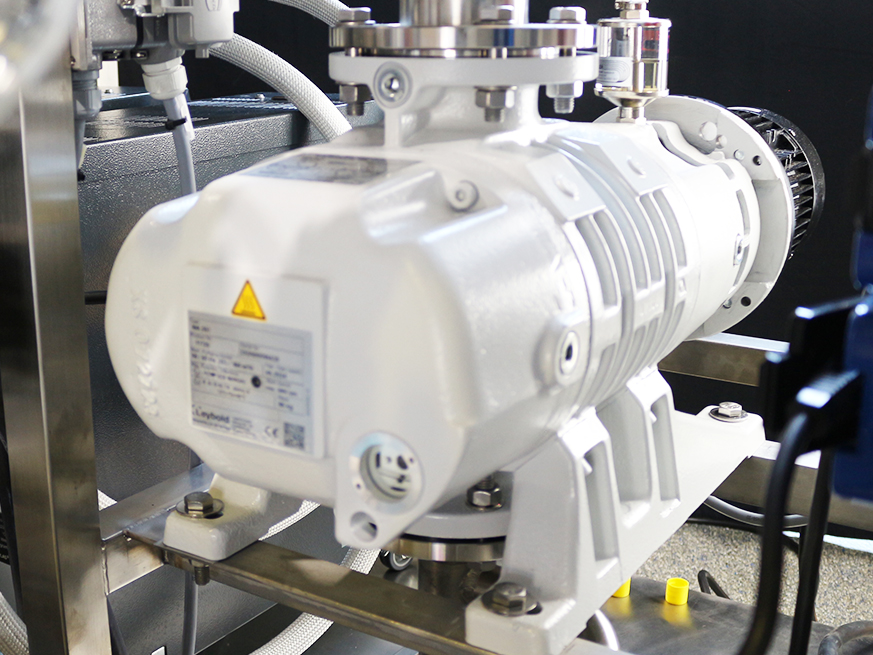

Ersetzt die standardmäßig verbaute Öldiffusionspumpe. Dies ermöglicht ein stabileres und besser kontrollierbares Vakuum, da die Leistungskurve einer Roots-Pumpe linear und nicht logarithmisch verläuft, wie die einer Öldiffusionspumpe.

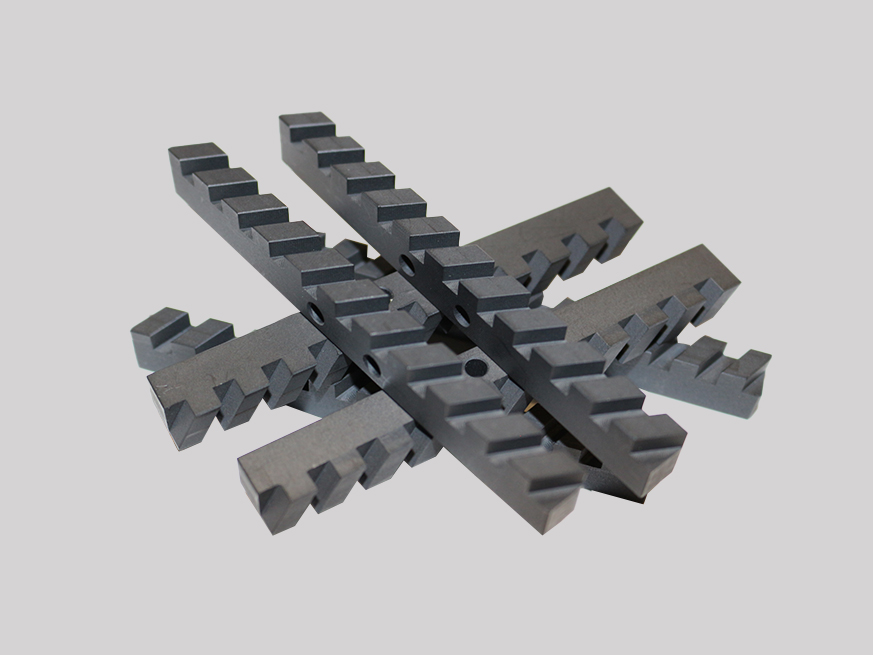

Ein Blockwischersystem, das anstelle oder zusätzlich zum Standardrollenwischersystem geliefert wird.

Wird empfohlen für Produkte mit Viskositäten über 1.000 mPas oder zur Polymerisierung neigende Produkte.