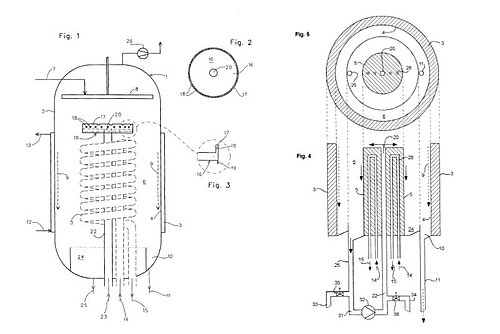

A short-path evaporator is used to process heat unstable products at low operating pressures and short residence times on a wiped evaporator wall and to evaporate the lighter components from a product film. The low operating pressures are mainly achieved with the basic design principle of the short-path evaporator, in which the condenser is installed centrally and opposite the evaporator wall. The evaporated fractions have a short path from the evaporator wall to the condenser - also called internal condenser. Therefore, the pressure losses in the process chamber are extremely low and low operating pressures can be achieved in the evaporation and condensation chamber, thus lowering the boiling points of the components to be evaporated. During the distillation of various products from the polymer, food, pharmaceutical, recycling, fragrance and flavor industries, deposits can occur on the internal condenser. These deposits can be entrainments of concentrate components that are mechanically transferred to the internal condenser. The deposits can be caused by higher melting components or also salts or polymer components.

It is also possible that high-melting components reach the internal condenser by evaporation and are condensed on the cold surface as solids.

To avoid solids on the internal condenser, there are several commonly known possibilities.

- Entrainment of concentrate components onto the internal condenser can be avoided as far as possible by using entrainment separators installed in the short path evaporator. These separators prevent non-distilled and high boiling products from getting onto the internal condenser and are installed between the evaporator wall and the internal condenser.

- Higher melting components which are transferred either by entrainment or by distillation and are collected as solids on the internal condenser, may be removed by increasing the condenser temperature above the melting point of the deposits in order to liquefy the collected solids.

If both of the described measures to avoid the deposits on the internal condenser are not successful, the use of the washing condenser is an option. Here, the solid components are dissolved in the washing liquid and discharged with it from the short path evaporator.

UIC GmbH, a sister company of VTA GmbH & Co. KG, has developed this technology and has used it in various plants. There are also various publications from which information on this technological solution can be obtained. See, among others, DE102006012866A-2006-03-19; EP2007002174W-2007-03-13.

With this technology, the internal condenser is flushed with a suitable washing liquid, deposits cannot form and are washed off directly from the condenser tubes. The washing liquid contaminated with solids can be reprocessed during operation using suitable process methods. With this technology of UIC GmbH (a VTA sister company), and the use of the scrubbing condenser, the Short Path Distillation can be used in continuous operation for such process-engineering demanding tasks.

See picture above: Fig. 1 and 2: From UIC GmbH patent "PROCESS FOR REMOVING VOLATILE COMPONENTS FROM A SUBSTANCE MIXTURE AND APPARATUS FOR PERFORMING THIS PROCESS”