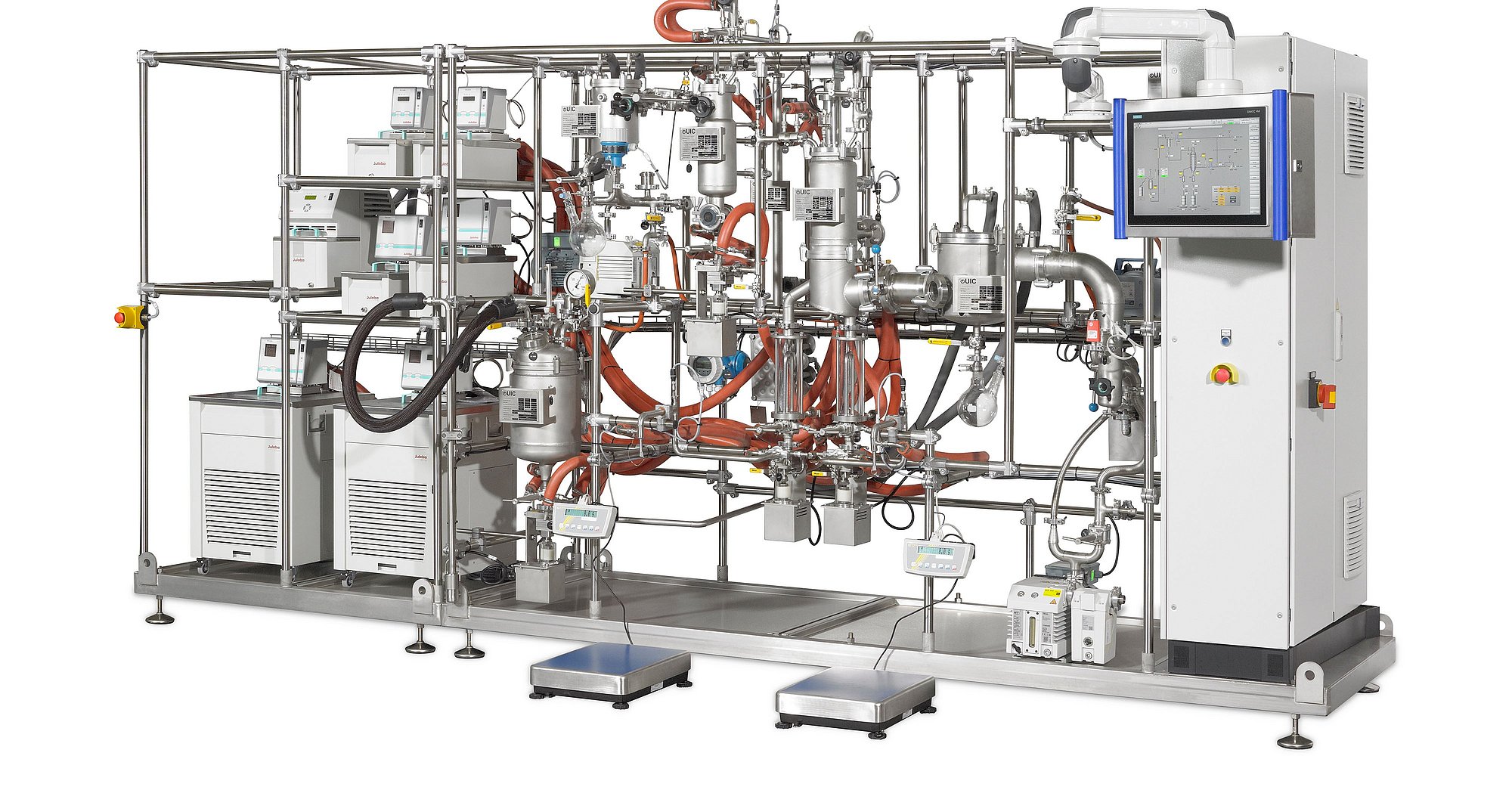

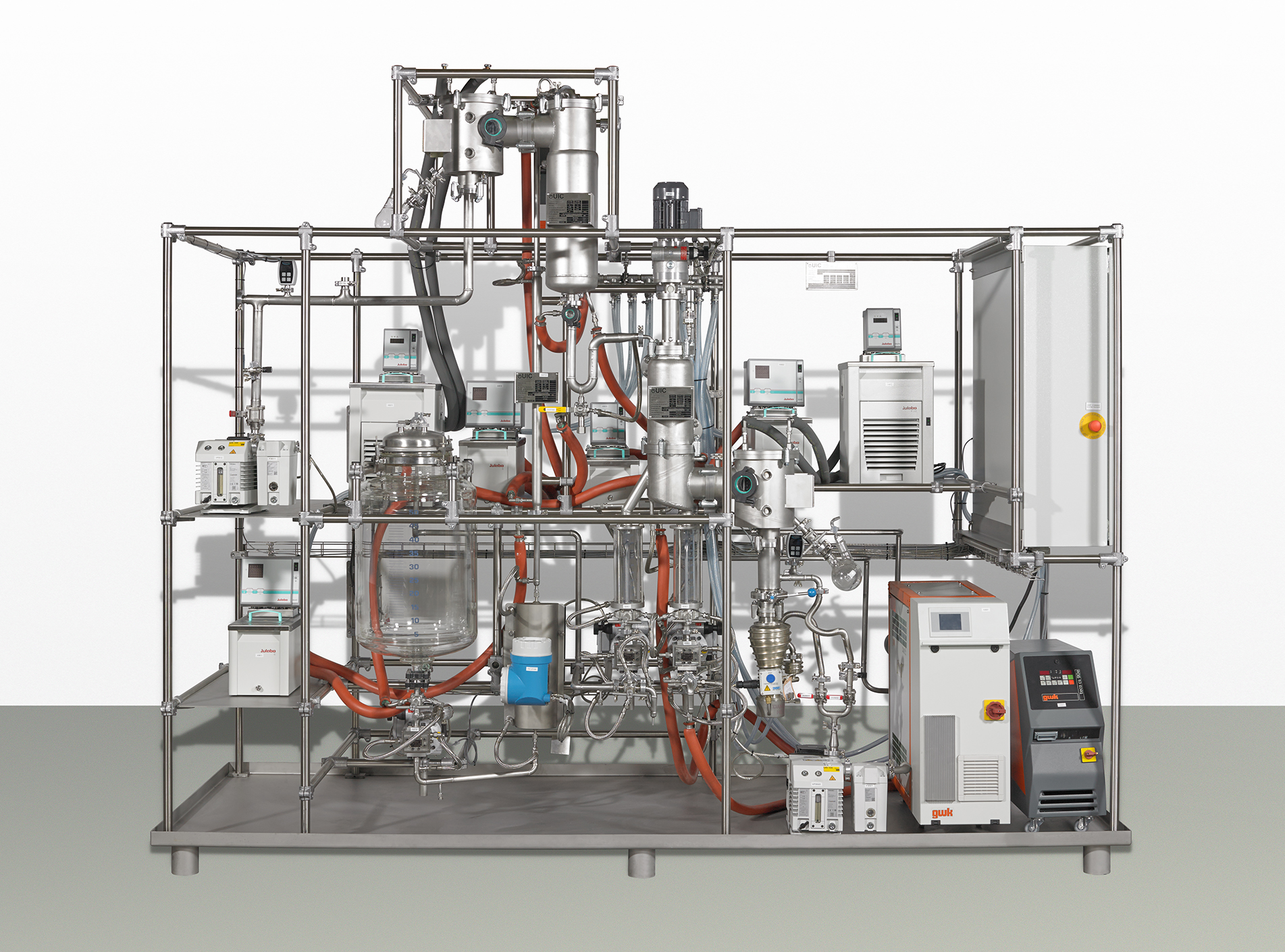

UIC pilot plants with Thin Film evaporators RF and Short Path evaporators KD offer everything you need for continuous distillation of your products.

They can be used for process development as well as for small-scale production. All important information for an upscaling process, process development and process optimisation

can be generated with the support of our pilot plants.

Among others, our pilot plants provide answers to these questions:

Which set-up and which setting provides the optimal product opportunities?

Where can temperature be reduced and thus energy saved?

How much throughput is possible with the planned distillation target?

Our pilot plants are also an integral part of our in-house innovation centre.

The knowledge gained from many different processes, is used to constantly check and improve the performance and quality of our plants.

Different models available covering different requirements

Product development on a small production scale

Scale up to industrial plants