UIC supplies plants for Thin Film, Wiped Film and Short Path distillation on laboratory, pilot and industrial scale. Each of our plants fulfills the set task in

the process and thus ensures the desired product quality, purity and yield.

Your developed process solution as a customized plant

All process engineering equipment of our plants is manufactured at UIC in Alzenau-Hörstein and within the STREICHER group of companies, where we combine our know-how in development, design and manufacturing. Thus, we offer our customers a fast response time and short delivery times.

Due to our high vertical range of manufacturing, we can guarantee highest quality standards and adapt the plants to the requirements of our customers. Our expertise in manufacturing plants with Thin Film (or Wiped Film) evaporators and Short Path evaporators has made us a trusted partner for companies all over the world.

Your benefit

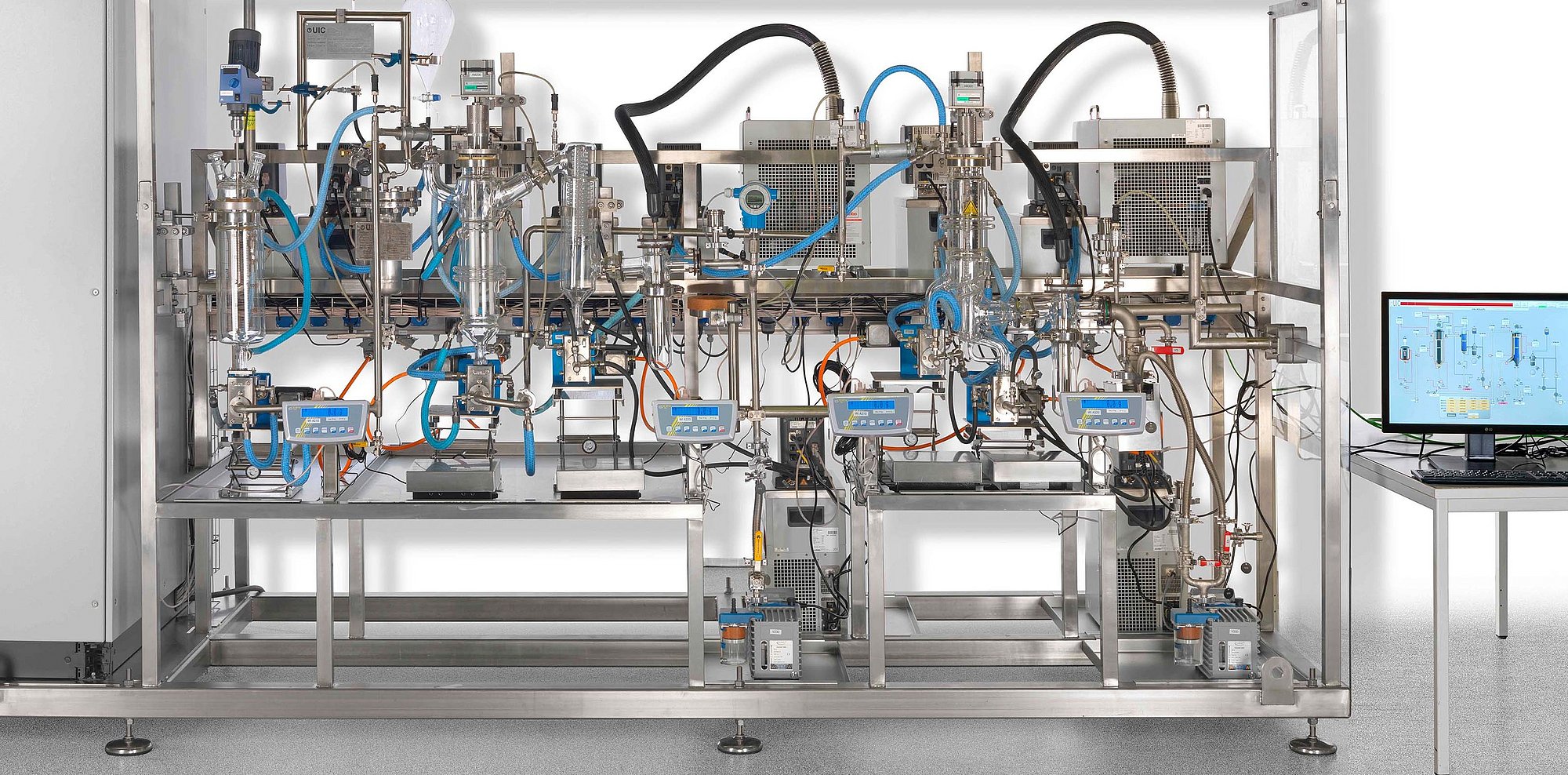

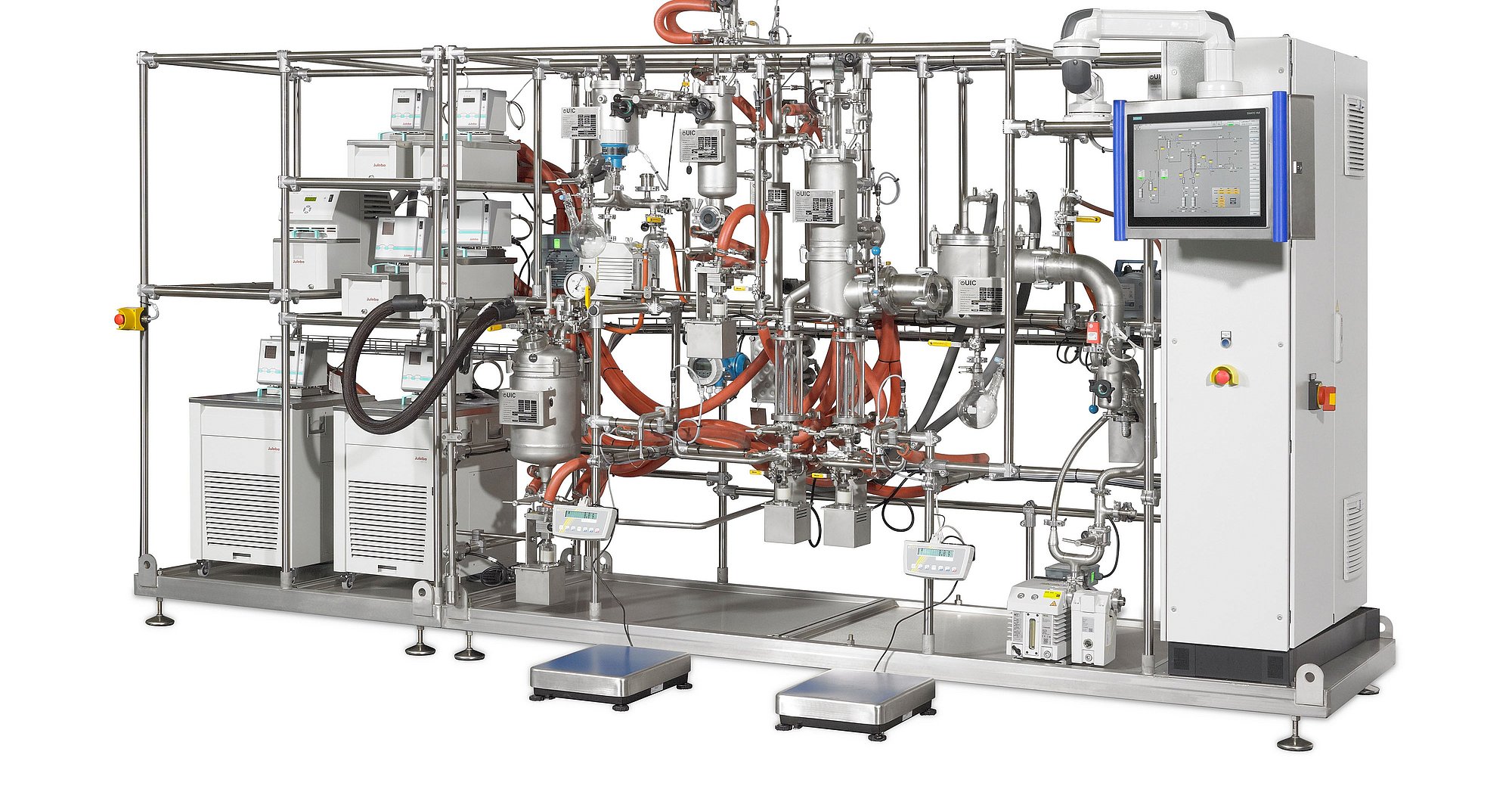

In our turnkey plants, so-called Package Units, all components are already pre-assembled in steel modules. The modules usually only need to be integrated into your existing infrastructure on site. Due to the quick and easy assembly of the plant on site, the commissioning of the plant can be carried out within a very short time and thus a possible interruption or impairment of the running production can be kept as short as possible.

According to your requirements for the scope of supply, such as evaporators, condensers, heat exchangers, vessels, pumps, valves, cabling, piping, instrumentation and relevant tests, the modules are designed and assembled. We take over the complete project management for you: engineering, specifications, HAZOP, design, documentation, assembly, commissioning, training and spare parts service.

Your benefit